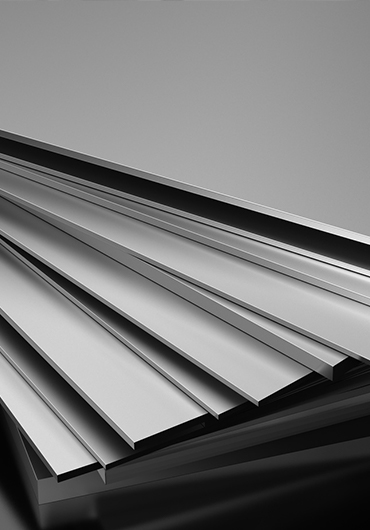

Stainless Steel Coils, Plates and Sheets

The nickel-molybdenum-chromium wrought alloy HASTELLOY C-276 is typically used for corrosion resistance. One of the more popular Hastelloy grades for general corrosion duty is Hastelloy C-276. A better worked form of Hastelloy alloy C is Hastelloy alloy C-276.

STAINLESS STEEL SHEETS & PLATES

Plates as per ASTM A240, Gr.TP 304,304L, 304LN, 309, 309S, 309H,310H, 316, 316L, 316H,316LN,316Ti ,317,317L,321,321H ,347,347H,409,410, 420, 430 etc.

STAINLESS STEEL PLATES, SHEETS & COILS SPECIFICATION

♦Stainless Steel Coils

Steel coil after rolling, a completed steel product such as sheet or strip that has been twisted or coiled Based on the knowledge gathered over the years, Renaissance Metal Craft Pvt. Ltd divides steel coils into hot and cold-rolled varieties, or stainless-steel coil, carbon coil, and galvanised steel, following current products and international standards.

Cold-rolled sheet in coil form is made by eliminating rust from a hot-rolled sheet by "pickling" it in a mild acid solution, then washing, brushing, drying, oiling, and unrolling the sheet, and lastly cold-rolling it by running it under pressure through a reduction mill and winding it into a roll. Cold-rolled steel is a more refined product with a smoother surface, greater dimensional precision (thickness, breadth, and length), and higher strength. The automobile sector uses a lot of cold-rolled steel, but it's also utilised to make home items.

Stainless steels are distinguishable from carbon steels by their chromium and, in certain circumstances, nickel presence. When chromium is added to carbon steel, it becomes more rust and stain-resistant, and when nickel is added to chromium stainless steel, it improves mechanical qualities such as density, heat capacity, and strength. A stainless steel sheet is used in the manufacturing of equipment, tools, and containers, among other things.

Carbon coil is a form of steel with few components other than carbon, silicon, manganese, sulphur, and phosphorus, and hence no substantial alloying element. Carbon coil is suitable for second-grade applications that do not place high demands on surface quality. Carbon coil steel from Renaissance Metal Craft Pvt. Ltd is available in several grades and thicknesses to accommodate the metal's numerous uses. Carbon coil is available in hot rolled, cold rolled, galvanised, aluminized, and painted forms. The following grades are available: CS-B, FS-B, DS-B, DDS, EDDS, A36, SS Grades 30-55, A572-50, HSLA Grades 40-80, and A606.

The galvanized coil is created by coating hot or cold rolled sheets or strips with zinc using either the hot-dipping or electrolytic deposition procedures. The zinc coating deposited by the hot dip process is often substantial enough to prevent corrosion without the need for additional protective coating. Because of the thin zinc coating, materials electro galvanized are not suitable for corrosion-resistant applications without following chemical treatment and painting, especially in moderate corrosive circumstances. Galvanize is a zinc-based coating. Galvanneal is the outcome of a unique heat-treating technique that turns the pure zinc coating into a zinc/iron alloy coating. Galvanized sheet is utilised in a variety of industries, including the automobile sector and the manufacture of roofing materials (e.g., flashing, guttering).

♦Stainless Steel Plates

Stainless steel is simply low-carbon steel that includes 10% or more chromium by weight. This chromium addition provides the steel with its distinctive stainless, corrosion-resistant qualities.

Because of the steel's chromium content, a rough, adherent, invisible, corrosion-resistant chromium oxide coating forms on the steel surface. If this film is physically or chemically damaged, it will self-heal if oxygen is present, even in small amounts. Increased chromium concentration and the inclusion of additional elements such as molybdenum, nickel, and nitrogen improve the steel's corrosion resistance and other beneficial qualities.

There are about 60 different grades of stainless steel. The entire group, however, may be split into five families. Each is characterised by the alloying components that impact its microstructure and are known as alloying components.

As a stainless steel plates manufacturer the stainless steel plate we manufacture by using an HRAP (hot rolled annealed and pickled) steel mill process, which results in a very strong and durable product that may be utilised for a variety of unique purposes. Overall, stainless steel tubing is a very valuable metal product because of its outstanding resistance to high heat, high pressure, salt, and other damaging substances.

HRAP (Hot Rolled Annealed and Pickled) Process

As a stainless steel plates manufacturer we describe how a hot rolled piece of stainless steel plate is completed once it has been manufactured. The word "pickled" refers to the material having been exposed to an acid solution designed precisely to remove the high temperature oxides that occur on the surface following annealing or welding. As a stainless steel plate manufacturer the removal of these oxides' aids in the restoration of the stainless steel's natural corrosion resistance. Pickling solutions can be applied to stainless steel by soaking it in a bath, spraying it, or applying tiny quantities of a pickling paste with a paintbrush.

Stainless Steel Plate Applications

As a stainless steel plates manufacturer our professionally manufactured stainless steel plates are utilised in a variety of sanitary services, food product handling, and construction applications that need corrosion resistance and hygienic material properties. Among the common applications for stainless steel plate products are:

- Hospital Equipment

- Marine Hardware

- Back Splashes

- Food & Beverage

- Kitchen Appliances

Stainless Steel Plate Benefits

As a stainless steel plates manufacturer the stainless steel plate we manufacture is also known as 'corrosion-resistant steel' because it does not discolour, corrode, or rust as easily as regular carbon steel. It would, however, be deceptive to claim that it is corrosion-proof. As a stainless steel plates manufacturer the product varies greatly from conventional carbon steel because of the quantity of chromium present, which inhibits surface corrosion in contrast to carbon steel, which rusts when exposed to air and moisture in the environment. As a stainless steel plates manufacturer we can assure you that stainless steel is a popular choice due to its anti-oxidation properties. Other advantages include simple fabricate, corrosin prevention, exquisite aesthetics, excellent hygiene characteristics.

Premium Quality Stainless Steel Plate Products

Renaissance Steel is among the leading stainless steel plates manufacturer of HRAP (hot rolled annealed and pickled) steel mill products are appropriate for a wide range of industrial applications and offer several characteristics and advantages. As a stainless steel plates manufacturer of highly useful stainless steel plate items at Renaissance Steel will provide the superior quality that your applications require.

Types of stainless steel plates

As a stainless steel plates manufacturer there are several stainless steel plates to pick from, however the most popular among consumers are as follows:

Austenitic stainless steel: The predominant microstructure of this steel is austenite, which is a solid solution of iron and carbon. This solution has a temperature greater than 723 degrees Celsius. This stainless steel family is robust, stunning, and resistant to high temperatures. This steel is made up of three separate metals: 70% austenitic, 16% chromium, and 6% nickel. As a stainless steel plates manufacturer this stainless steel grade is nonmagnetic, and heat treatment will not quickly harden it.

Ferritic stainless steel: Ferritic steel is alloyed only with chromium. The chromium content fluctuates between 10.5 and 18%. As a stainless steel plates manufacturer this steel possesses a variety of metallic qualities, including corrosion resistance and magnetic properties, and heat treatment does not harden the metal. Overall, they are resistant to stress corrosion.

Martensitic stainless steel: As a stainless steel plates manufacturer this steel's distinguishing characteristics include greater carbon and lower chromium. It is magnetic, has good weldability, and has better hardenability. Heat treatment can improve the characteristics of this metal. Corrosion resistance may be ower in aluminium than in the other two metals.

Advantages of stainless steel plate

Stainless steel plates were invented in the early twentieth century and have a long history. Stainless steel plate offers several advantages, including a smooth surface, high plasticity, toughness, and mechanical strength, and resistance to corrosion in acids, alkaline gases, solutions, and other media. As a stainless steel plates manufacturer, we can tell you that it is an alloy steel that is resistant to rust but not rust-free.

Stainless steel plate refers to both stainless steel plate and acid-resistant steel plate. As a stainless steel plates manufacturer our stainless steel plates are resistant to corrosion by weak media such as air, steam, and water, whereas acid-resistant steel plate is resistant to corrosion by chemical corrosive media such as acid, alkali, and salt. As a stainless steel plates manufacturer, we can tell you that since the introduction of stainless steel plates at the turn of the century, the development of stainless steel plates has provided an essential material and technical foundation for the advancement of contemporary industry and technological progress.

As a stainless steel plates manufacturer, there are many distinct types of stainless steel plates and steel plates with various qualities that we manufacture. During the growth process, it eventually established different categories. As a stainless steel plates manufacturer during the manufacturing process the steel plate is divided into four categories, according to the organizational structure: austenitic stainless steel plate, martensitic stainless steel plate (including precipitation hardened stainless steel plate), ferritic stainless steel plate, and austenitic plus ferritic duplex stainless steel plate.

As a stainless steel plates manufacturer steel plate's main chemical composition or some distinguishing elements are classified as chromium stainless steel plate, chromium nickel stainless steel plate, chromium nickel molybdenum stainless steel plate, low carbon stainless steel plate, high molybdenum stainless steel plate, high purity stainless steel plate, and so on.

As a stainless steel plates manufacturer most frequent categorization approach is based on the structural features of the steel plate, as well as its chemical makeup, or a combination of the two. It has several applications. As a stainless steel plates manufacturer, the common applications of our stainless steel plates include heat exchangers for pulp and papermaking equipment, mechanical equipment, dyeing equipment, film washing equipment, pipelines, external materials for coastal structures, and so on.

As a stainless steel plates manufacturer our stainless steel plates have several advantages. Let's take a look at the corrosion resistance, high temperature oxidation resistance, and physical qualities of stainless steel plates.

Corrosion resistance: As a stainless steel plates manufacturer our stainless steel plate is resistant to general corrosion in the same way as the unstable nickel-chromium alloy 304 is. Long-term heating in the chromium carbide temperature range may damage alloys 321 and 347 in strong corrosive conditions. Excellent temperature applications necessitate materials with high sensitization resistance in order to prevent intergranular corrosion at lower temperatures.

High temperature oxidation resistance: As a stainless steel plates manufacturer our stainless steel plates are resistant to oxidation at high temperatures; however, the rate of oxidation is determined by fundamental characteristics such as exposure environment and product shape.

Physical properties: As a stainless steel plates manufacturer, the metal's overall heat transfer coefficient is affected by variables other than its thermal conductivity. In most circumstances, the film heat dissipation coefficient, scale, and metal surface condition are all taken into account. Because stainless steel can maintain a clean surface, it can transmit heat more effectively than other metals with higher thermal conductivity. As a stainless steel plates manufacturer, the stainless steel plates we manufacture high-strength stainless steel plates with good corrosion resistance, bending workability, welding part toughness, and welding part stamping performance and production processes.

The Many Uses of Stainless steel Plates

As a stainless steel plates manufacturer our stainless steel plates are utilized for a wide range of applications and goods for a variety of reasons. One of the primary reasons is its excellent resistance to oxidation and corrosion. It is also abrasion resistant and simple to clean.

As a stainless steel plates manufacturer our stainless steel plates (and stainless steel in general) are also simple to produce, have a clean and appealing look, and are very light while being quite robust. These are also rather pliable without sacrificing strength, making them perfect for a variety of applications.

As a stainless steel plates manufacturer our stainless steel plates (and stainless steel in general) are also simple to produce, have a clean and appealing look, and are very light while being quite robust. These are also rather pliable without sacrificing strength, making them perfect for a variety of applications.

Because of its adaptability, strength, and corrosion resistance, as a stainless steel plates manufacturer our stainless steel is employed by a wide range of industries and businesses. The application of these plates is frequently determined by the plate grade. With so many plate grades available, you can be certain that this metal will be employed for a wide range of applications.

As a stainless steel plates manufacturer there are various grades used to categorize stainless steel plates are made up of numbers and numbers combined with the letters H and L. The steel plate grade determines which industries utilize this metal and for what purpose. As a stainless steel plates manufacturer our stainless steel plates are engraved with letters and grades which determines where it may be utilized.

The letters H and L in stainless steel grades frequently indicate whether the steel has a low or high carbon content. L stands for low carbon stainless steel plates, whereas H stands for high carbon stainless steel plates. When a plate grade lacks any of these two letters, it is referred to as a straight grade. Straight grade stainless steel is known to include at least.08% carbon, although there is no regulatory requirement that these metals contain a minimum quantity of carbon.

Here are some of the more typically manufactured stainless steel plate grades as a stainless steel plates manufacturer used to help you understand the usage of these distinct stainless steel grades:

304 Stainless Steel PlateThis is available in three grades: 304, 304H, and 304L. As a stainless steel plates manufacturer this plate grade, which is part of the 300 series, is commonly used in the food and beverage sector. This is because this grade has the potential to limit contamination possibilities to a minimum. This metal comprises approximately 18% chromium and approximately 8% nickel.

316 Stainless Steel PlateAs a stainless steel plates manufacturer this grade, which is also part of the 300 series, has 16% to 18% chromium and 11% to 14% nickel. Because of its resistance to corrosion caused by saline water, this is frequently utilized in environmental and marine applications.

410 Stainless Steel PlateAs a stainless steel plates manufacturer this is a heat treatable steel that may be used to make surgical tools as well as strainers for the food industry.

Features of Stainless-Steel Plates

Uniform quality

An integrated quality system ensures uniform quality in products with exceptional formability and corrosion resistance from steel production through the final process.

Attractive Finishes

Stainless steel finishes are preserved in pristine condition at all times, and automated control technology is employed to ensure great dimensional correctness. Renaissance Metal Craft Pvt. Ltd 304L has received widespread praise for its superior quality and gorgeous shine.

Products for Every Application

Renaissance Metal Craft Pvt. Ltd has a large selection of stainless-steel kinds. Most stainless-steel manufacturers in China may be combined by Renaissance Metal Craft Pvt. Ltd. If you have special demand, please contact us so that we may find better options.

Excellent Corrosion Resistance

The atmospheric corrosion resistance is particularly visible, as is the welded area.

Price Competitiveness and Stability

Even when the price of nickel and molybdenum raw materials skyrockets, the price of the stainless plate without nickel is lower.

Good Formability

When compared to other conditional stainless steels, it has the same or greater formability.

Excellent Physical Properties

Stainless steel from Renaissance Metal Craft Pvt. Ltd has superior thermal conductivity, a lower thermal expansion coefficient, and a lower material weight for the same size as other providers.

Heat Resistance

304 offers strong oxidation resistance in intermittent service up to 870°C and continuous operation up to 925°C. Continuous usage at 425-860°C, on the other hand, is not advised if water corrosion resistance is necessary. Because of its resistance to carbide precipitation, 304L is suggested in this case.

Grade 304H is indicated for high strength at temperatures over 500°C and up to 800°C. This material will remain resistant to water corrosion.

Fabrication

All stainless steel should be manufactured using only stainless steel-specific tools. Before usage, all tools and work surfaces must be well cleaned. These measures are required to avoid cross-contamination of stainless steel by readily corroded metals, which may discolour the surface of the manufactured items.

Cold Working

304 stainless sheets of steel work harden easily. Cold working fabrication processes may necessitate an intermediary annealing cycle to ease work hardening and prevent ripping or cracking. A thorough annealing procedure should be used after manufacture to decrease internal tensions and optimise corrosion resistance.

Hot Working

Fabrication processes involving hot working, such as forging, should occur after consistent heating to 1149-1260°C. To provide optimal corrosion resistance, the produced components should be immediately chilled.

Heat Treatment

Heat treatment cannot harden 304 stainless steels. Rapid cooling following heating to 1010-1120°C might be used for solution treatment or annealing.

♦Stainless Steel Sheets

Stainless steel sheet metal and plate items are less likely to discolour, corrode, or rust than carbon steel. A stainless steel sheet and the plate are widely sought-after metals for applications needing a durable metal with favourable anti-oxidation rates due to its enhanced strength, impact resistance, anti-bacterial characteristics, and aesthetic appeal.

Stainless steel, often known as Inox steel or Inox from the French word "inoxydable," is a steel alloy having a minimum chromium concentration of 10.5% to 11% by mass. Nickel, molybdenum, and niobium levels are present in Balance.

Although stainless steel is resistant to corrosion, it is not completely stain-proof. When the alloy type and grade are not stated, it is sometimes known as corrosion-resistant steel or CRES (specifically in the Aerospace industry). Stainless steel comes in a variety of grades and surface treatments to suit a wide range of applications. Stainless steel is mostly employed when both steel mechanical characteristics and corrosion resistance are required.

Stainless steel is used in a variety of sectors, including Aerospace, Automotive, General Engineering, Oil & Gas, High Tech, and Medical.

There are several grades of stainless steel, each having a unique combination of iron, chromium, nickel, and other metals that give them their distinctive features and characteristics. The crystalline structure divides these stainless steel grades into five categories: austenitic, ferritic, martensitic, duplex, and precipitation-hardening. We have a lot of experience with the 300 series and 17-7 Precipitation Hardened steel, which are nonmagnetic nickel-based alloys that come in annealed (very formable) and hard tempers.

The 300 series stainless steel sheets are the most common austenitic stainless steel subgroup. The austenitic Type 304 (also known as 18/8 or A2) stainless steel grade is the most often used in domestic and industrial applications like food processing equipment, screws, machinery parts, and external architectural features. Renaissance Metal Craft Pvt. Ltd sells a variety of high-quality stainless steel, each grade individually designed to function under certain situations. Renaissance Metal Craft Pvt. Ltd has thin steel sheets, foils, and strips to meet your specifications.

Photo and chemical etching, laser and waterjet cutting, and precision stamping are used to treat materials. Our high-quality stainless steel for sale is utilised in the production of a wide range of commercial and aerospace equipment, including:

- Shims

- Laminated shims

- Gaskets

- Washers

- Formed parts

- Automotive

- Marine

- Medical

- Aircraft / Aerospace / Military

EXPORT COUNTRIES

Ethiopia | South Africa | Ghana | Tanzania | Argentina | Bolivia | Brazil | Chile | Colombia | Ecuador | Guyana | Paraguay | Peru | Suriname | Uruguay | Venezuela

Our Products

Send us your enquiry today

We respond to all enquiries within 24 hours. Click on contact to send your requirement.

Contact us